01. Safety in workshop

- Always keep the workshop clean

- Always follow the workshop rules before entering workshop

- Use safe tools while working in workshop

- Wear safety shoes, apron or boiler suit while working

- Wear safety hand gloves

- Use a proper holder and hand gloves to carry hot material

- Use safety googles

- Before using machine check its oil level , greasing and servicing

- Don"t miss behave while working on machine

- Use Fire preservative while any case of fire in workshop

- Turn of the main switch in case of an accident o machine

- Keep raw material or scrap in proper place to reuse it

- Always keep the windows open of workshop

- always keep the entry of the tool

- Don't miss behave in workshop while working

- Don't make an working area crowded

- Don't trow tool anywhere

F.A.Q.:-

- why to check the oil level of the machine

- which type of hand gloves are required in workshop

- what type of safety should be taken

- why to keep window open

- how to prevent fire in case of accident

02. Information about tool and machine

Piler Drill machine :- use to make 1-25 mm hole in material or job

Practical No:- 3

3] measurementLet's see if there are two methods of measurement

British methods: - Inches, feet, koos, scum, pand, parsa, dozen, mind, stage, weavers,

Metric Methods: - Centimeters, meters, kilometers, kilograms, acres, humus, tons,

Micron, ton, liter ......

12 inches = 1 ft

1 inch = 2.5 centimeters

1 man = 40 kg

1 quintan = 100 kg

1 ton = 1000 kg

1 modular = 1/2 kg

1 stage = 5 kg

1 dozen = 12 nos

1 block = 20 nos

3.3 feet = 1 meter

30 centimeters = 1 ft

1 ft = 300 [mm] millimeter

1m = 3 9inch

1 centimeter = 10 mm

100 centimeters = 1 meter

1000m = 1kg

1 kg = 100 g

1 liter = 1000 milliliter

40 gunthas = 1 acre

2.5 acre = 1 hectare

4000 meter square = 1 acre

108 9square Foot = 1 Guntha

When splitting an inch it has to be divided by 12.

12 times when inches of crop is multiplied.

The centimeters have to be divided into 100 meters.

In the millimeter centimeter, 10 divided by 10

It takes 1000 times for kilometer meters.

1000 meters of meter should be divided by 1000.

Inches of centimeters 2 5 to escape.

Inches centimeters 2 5 has to multiply.

3 times when the meter breaks 3 has to multiply.

3 times in filaments 3 has to divide by.

30 centimeters of fate has to be multiplied.

It is necessary to divide 30 by centimeters of rupture.

A meter should be divided by 1,000 meters.

Multiplied by 1000 by millimeter meters.

1 brass = length * width * height

/ 100

1 brass = 100 cubic feet

After practiculating, the measurements measured by workshops in feet, meters and kilometers are as follows:

Front side rear side

Feet = 72 ft 5 in ft = 72 ft. 5 in

Meters = 22 meters meters = 22 meters

Kilometers = 0 022 kilometers kilometers = 0 22 Kms

The north side of the north side is the southern side

Ft = 83 ft 3 in ft = 83 ft. 3 in

Meters = 25 meters 36 cm meters = 25 meters 3 centimeters

Kilometers = 0 025 kilometers kilometers = 0 25 kilometers

* The next and previous sides of the workshop were the same.

The southern and northern sides of the workshop were the same.

That is, the sides of the workshop are the same.

Practical No: - 4

4] welding .....

Welding means: -

Welding is the means of merging the same material with the same metals as the welding.

Use the same type of rod as a welding welding material.

Used in a step-by-step transformer to reduce the voltage in the welding machine.

Hold Holder Cable Meaning Cable One machine can be attached to two holders.

Flux, on the welding road, says: -

Flux is made of metal known as covoline. Flux is made from starch, chalk, D oxygen.

Now let's see the functions of the objects that we create flux.

Function of Cavolin: -

Binder work. Pinch

Starch Chalk or Choice of Work: -

Prepare the Gas.

D oxygen: -

The place where welding is done

Air connectivity in those places

Rod has several companies. The difference in the rod as the company changes

Is there.

Gauge

Jadi Road

Length

Grinding

Voltage

12

2.5mm

350mm

125

11-125

10

3.15mm

350-3450mm

90

90-130

8

4.50mm

350-450mm

60

140-190

6

5mm

450mm

40

170-230

Just as the thickness of the road increases and the thickness of the road increases as the gauge decreases, the gauges decrease.

Practical No: - 5

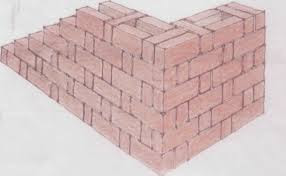

5] Studying the design of bricks ......

There are five types of bricks for the construction of different sizes of bricks to build in a specific way during construction. The types are as follows:

Stretcher Bond: -

In this bond, we can see only width and ink when looking at Vita.

Header Bond: -

In this bond we can see only width and height when looking at bricks.

English Bond: -

In this English bond, we use a substrate like a substrate and another sub-header bond. They are called English bonds.

Flemish Bond: In this bond we use a brickbreaker bond and a brick herders bond. That construction can strengthen our walls.

Rap-Tap Bond: -

In the construction we build the works by placing bricks. There is a burst of bricks in this construction. The air comes from outside air and inside air. So it's called rap-trap.

Practical No: - 6

6] Blocking ....

Vitta has 3 sides: -

1] The stretcher side

2] Header side

3] Frog side

Bricks are soaked in water while construction, as the cement and sand goods we manufacture. Their water absorbs bricks.

Let's see the ratio used to construct and plaster: -

Construction is 1/6 ie: - 1 cubic cement of 6 grams sand

.

Plaster 1/3 means: - 1 gram cement 3 grams sand.

* If there is a sand and cement mix, the monitor is created.

* Cuddy-Wool-Symmetric mixer creates a jacket.

Water in Bamankamam: -

Watering is called quilling.

* Badhankam has to be killed for 21 days.

Spirit level: - The time we interfere. This is used to measure rope or level level.

Level Tub: -

The level tube is used to show the same level, that is, the level tube is used to equal the height at long distances. Any substance always remains parallel to the mass.

Curvature: - If any object is thrown over it, it can be dragged down to 90 degrees. Image result for valamba tools

Practical No: - 7

7] length machine

* Information: -

Length machine is a big machine and it is very heavy. She can not be anywhere or leader. With the help of this machine, the iron or wood objects can be shaped as desired. The cost of this machine is generally at least 75. / Starts from With the help of this machine we can shape the following ways.

Casing: - Reducing or decreasing the length of wood or iron. It is used for

Turning: - With the help of this tool, we can reduce the thickness of wood or iron.

Naralinga: With the help of this tool, we grip the wood or iron

May be.

Trapping: - With the help of this tool, we can tap wood or iron for the next part.

Coping: - With the help of this tool, we can give thread to the inside of wood or iron.

With the help of all these tools, we can enhance the beauty of wood or iron by giving it a better shape. And parts of different goods can also make different things.

Practical No: - 8

8] Plugging

* c.p.v.c means a pipe used for hot water.

* u.p.v.c means pipe used for cold water.

Materials required for plumbing.

1] Haxo 5] sieve / hammer

2] Raining the wings 6] Baker

3] Solution 7] Drill machine

4] Tap lone tape 8] Cutter machine

* Pipe joint type: -

1] El Bo 5] Socket

2] T-Joint 6] Union

3] id cap 7] Kappling

4] Redsore

* 1] Still pipe bread = 25%

2] g.i pipe = 75%

3] Copper Pipe

4] c.i pipe

5] p.v.c pipe

Practical No: - 9

9] footing

Tools: - Iron rod, rope, eagle tape, randha, hammer, line rope,

Spirit Level, Level Tub, Thapi

Purpose: - Learning to construct by laying the foundation.

There are three methods to build houses, columns, foundations, foundations.

We had to prepare the cloth for the plant. For this we have used this method of foundation and foundation.

Action: - Bring all the material equipment to workplace. 2] The first point

Fix it Right angle and tape measure with second pitch

Took it Two or two rods are applied outside the point. And the order is constructed by the measurement of the fourth layer and

The foundation was marked by the foundation. The fourth and the feet of the construction

Use different marking marks. Each angle

It should be 90 °. For this, we measure the distance of 8ft by the width

Take the foundations dig. In construction we prepare goods as 6: 1

Was done.

Inspection: - All the bees who have 90 ° C while doing the foot.

Conclusion: - Placing the foot before the house construction. Needed

Learn how it is.

Practical No: - 10

10] Making nuns and replacements from the letter of the letter.

Objective: - By making letters in a proper measure from the letter of the letter

Marking with it, cut off the letter and put it in a round shape.

Materials / Tools: - Letter sheet, letter cutter, hammer, bandage, pencil,

Sawding machine

The use of nerds is used to fill the kerosene and oil into the drum.

You used nonsense to fill any liquid foods.

When making a narsale, the first 10 cm lines were drawn and one center was drawn. She removes 8 cm long lines. And in which the use of the computations is more and the 8 mm is removed as a circle to see the upper part of the Narna. And the goal was scored at the goal.

Practical No: - 11

11] Threading and tapping.

Objectives: - Threading and tapping.

Bit, tap, thread, thread

Three types of tapping

1] Primary tap

2] Secondary tap

3] Taper Tap

Tapping means: - Creating a way to fit the bolts inside the first hole. The first drilling of any hole is done. After tipping, the tipping is done after rimming. Drilling means hulling rimming, ie tapping the hole. That's to be threaded inside the hole.

Method: - 1] [50 * 50 * 5] Plate the plate of mm.

2] Align four sides of that square plate.

3] Removal of rust after it has been removed.

4] He fixed the square plate drill machine's whistle.

5] and drilled the first drill on it.

6] The finished hole rimer was cleaned.

7] The primary tap fix in the stroke was fixed.

8] She pulled the steel plate in the bench whichey and measured the honeycomb along with her on the first tape.

9] It was done once or twice.

10] Fit in secondary diastoke and complete second tap.

11] While doing this, cutting oil used in-in-time.

12] Then topper tape was used.

13] Tap has two types.

1] British 2] matriculation

The British top plates are very small.

And that's the big one.

The space in the matrix top thread is low.

14] So three tapes are complete.

Estimates / Conclusions: -

In the above process we learned to thread and tagging.

Inspection: -

Tapping should be done very carefully. When tapping, you should straighten the plate. If slip, tapping is slanted and all your payments.

Practical No: - 13

Attention: - Identifying the weapon in the workshop.

Requirements: - All weapons in the shipyard

Information: -

1) SAw: - The use of saw is to cut wood. The shape of the tooth is in v

2) Jack plain: - To plane the wooden surface and to clear the edges of the jod it is made up of wooden and iron material

3) Chisel: -

To remove the part from the job that is not required

4) Round file:- to remove and smooth the surface of the job

5) Oyil Stone: - use to sharpen the tools edges

6) Malate: -Use to give shape to the metal sheet or etc

7) Amber: -Use to remove the broken or bend nails

8) Hammer: -Use to hit nails and to remove

Practical No: - 14

Threading and tapping

Purpose: - To learn about trading and tapping.

According to the requirement: Take one bar of 18 mm to 12 mm orange, use dying stains and pipes

Procedure: -

Threading: - Roll the rod for the sub-use of gas according to the drum to return to be used for the death.

Tapping: - The right size drill hole at work Required holes size is required to light the drill to fit the top range. The size of the size is larger than the size of it, then the midterm is a meter hole, the cutoff bit is smaller than the tap range. You use oil as soon as you notice that oil is used for lubrication and cooling. They do not rotate hard by using the oil to rotate smoothly

Practical No: - 15

Ferro cement sheet

Our mission: - Prepare ferro cement sheet.

Need: - Construction equipment for equipment and equipment welding machine sharing machine.

Materials / Tools: - Sand, cement, water, weldma net, chicken mesh, 6 mm torch bar, GI wire 26 gauge etc.

Functions: - Choose to create. 45 * 45cm Make Ferro Cement Sheet (You can choose different shapes available locally and according to requirement.

1) 6 cm in length of 45 cm in length is 6 mm Cut the diameter rod.

2) Frame 45 * 45cm Put this rod to make the shape

3) Cut chicken mesh and welding net 45 * 45cm Size

4) Chicken mesh 1 inch hole or 12 gauge.

5) Weldmesh mesh 1 inch * 1 inch hole and 2.5 × 3 mm

6) GI Put a chicken nets and welding mesh in the frame using the wire.

7) Make a molter (1: 3 cement: sand mixture)

8) Place the paper on the size of the size of the frame size

9) Apply the rod frame on the paper

10) Mortify the frame.

11) Use it with a lid and apply it on it.

Inspection: -We look forward to the next day that our sheet is okay

No comments:

Post a Comment